- #Just in time inventory advantages how to#

- #Just in time inventory advantages full#

The Role of Just-in-time Delivery in Inventory Management

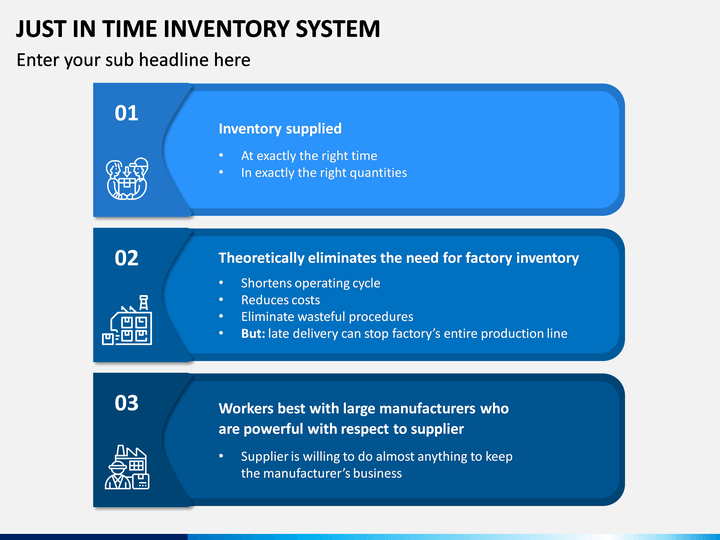

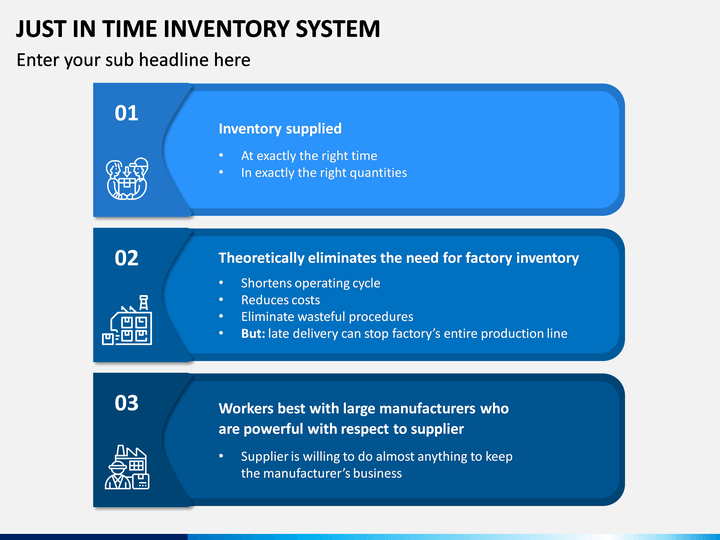

Then, as the logistics services, you are required to deliver the product just-in-time for the customer to use it, often within a day or two of the order being placed. Then, the supplier transports the final product to your warehouse or storage facility, from where you are responsible for delivering the product to the customer’s doorstep. The supplier receives the order and starts the production process, using raw materials and other resources required to manufacture the product. The customer places an order for a product. It can be useful, particularly for businesses that operate in fast-moving or highly competitive markets, where the ability to respond quickly to customer demand can be a key advantage. Just-in-time delivery requires close coordination between the supplier and the customer, as well as efficient planning and just-in-time logistics techniques to ensure that the right products are delivered to the right place at the right time. The idea is to minimize the storage problem and maximize productivity. To practice just-in-time delivery, the suppliers need to sync orders with delivery schedules. How does just-in-time (JIT) delivery work? This approach can help reduce waste, minimize inventory management costs, and increase customer satisfaction by ensuring that products are fresh and available when needed. It is a process of delivering goods to business customers rather than maintaining a large inventory of items that may not be used immediately.

Just-in-time (JIT) delivery is an inventory and supply chain management strategy aiming to minimize inventory and increase efficiency. Just-in-time delivery means the process of creating goods in a ready state or completing their production so that a minimal inventory can satisfy demand and delivery can take place with immediate effect in order that consumers receive what they want precisely when they want.

Level Up Your Just-in-Time Delivery Process With Upper Route Planner. Advantages and Disadvantages of Just-in-time Delivery.

Level Up Your Just-in-Time Delivery Process With Upper Route Planner. Advantages and Disadvantages of Just-in-time Delivery. #Just in time inventory advantages how to#

How to Implement Just-in-Time Services Successfully.The Role of Just-in-Time Delivery in Inventory Management.In this blog, you will get in-depth knowledge of what is just-in-time delivery and how it can be helpful in your business. Later, the US started adapting it in the late 1980s. To overcome this problem, Taiichi Ohno adopted the idea of just-in-time (JIT) at Toyota.

#Just in time inventory advantages full#

Full storages require various resources like electricity and labor, which increases the business’s overhead cost. Whereas sometimes, the demand is comparatively less, and the suppliers need to store the products in the warehouse for a longer time.ĭue to the uncertain demand-supply ratio, many industries are facing storage issues, and they are going out of space to store the products. Sometimes the demand is so high that the suppliers can hardly keep the products in the warehouse.

JIT delivery necessitates vigilant demand and inventory management, as well as adaptability to changing conditions.ĭue to industrialization, there is a high supply of products from the manufacturers’ side. By lowering the expense of keeping goods on hand and enabling businesses to make other investments, JIT delivery can increase cash flow. JIT delivery can boost productivity and cut down on lead times, but it necessitates close coordination between departments and with suppliers. Just-in-time (JIT) delivery is a strategy that can lower inventory costs and waste for firms, by ordering and receiving items only when necessary,.

0 kommentar(er)

0 kommentar(er)